JavaScript is disabled for your browser. Some features of this site may not work without it.

Buscar en RiuNet

Listar

Mi cuenta

Estadísticas

Ayuda RiuNet

Admin. UPV

Hybrid microwave with heat recovery for an efficient drying process

Mostrar el registro sencillo del ítem

Ficheros en el ítem

| dc.contributor.author | Deleu, Willem

|

es_ES |

| dc.contributor.author | Goovaerts, Vincent

|

es_ES |

| dc.contributor.author | Groffils, Carlo

|

es_ES |

| dc.date.accessioned | 2019-11-11T12:26:01Z | |

| dc.date.available | 2019-11-11T12:26:01Z | |

| dc.date.issued | 2019-10-15 | |

| dc.identifier.isbn | 9788490487198 | |

| dc.identifier.uri | http://hdl.handle.net/10251/130654 | |

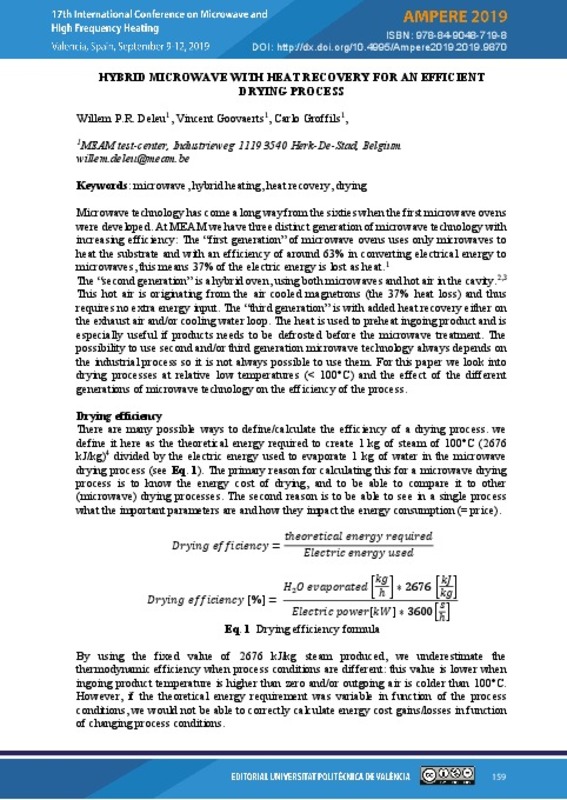

| dc.description.abstract | [EN] Microwave technology has come a long way from the sixties when the first microwave ovens were developed. This first generation of microwave ovens uses only microwaves to heat the substrate and with an efficiency of around 63% in converting electrical energy to microwaves, this means 37% of the electric energy is lost as heat. The first improvement to this system “second generation” is using hybrid heating with both microwaves and hot air. The hot air in this case is simply the air used to cool the magnetron and transformers that is blown into the microwave cavity. The 37% of lost energy can thus be reused. The first role of the hot air current is to remove moisture from the cavity to avoid condensation on the (cold) cavity walls. The second role is to insulate the hot product from the cold environment and prevent energy loss. The third role is increasing evaporation speed; this decreases drying time and can also keep the drying temperature low through evaporative cooling. Low drying temperatures are favored in many processes especially with food as it delivers a superior dry product.The “third generation” utilizes an additional heat exchange to further increase the system’s efficiency. The hot (wet) exhaust air is not fully saturated yet so it can be used to preheat the substrate before it enters the microwave cavity. A good example is thawing and preheating frozen starting material. If water cooled magnetrons are used, the hot air is replaced by hot water instead for the heat exchange. Microwave processes are generally much faster resulting in smaller machines and reduced operational area. When designing a microwave process all these factors need to be taken into account to result in the cheapest and most robust process. As heat exchange generally takes a long time, it should only be done to a degree that it does not slow down the microwave process. | es_ES |

| dc.format.extent | 7 | es_ES |

| dc.language | Inglés | es_ES |

| dc.publisher | Editorial Universitat Politècnica de València | es_ES |

| dc.relation.ispartof | AMPERE 2019. 17th International Conference on Microwave and High Frequency Heating | es_ES |

| dc.rights | Reconocimiento - No comercial - Sin obra derivada (by-nc-nd) | es_ES |

| dc.subject | Energy Production by Microwaves | es_ES |

| dc.subject | Microwave CVD | es_ES |

| dc.subject | EM Modelling | es_ES |

| dc.subject | Microwave Material interaction | es_ES |

| dc.subject | Dielectric Properties | es_ES |

| dc.subject | Dielectric Properties Measurement | es_ES |

| dc.subject | Solid State Microwave | es_ES |

| dc.subject | Microwave Processing | es_ES |

| dc.subject | Microwave Chemistry | es_ES |

| dc.subject | Microwave applicators design | es_ES |

| dc.title | Hybrid microwave with heat recovery for an efficient drying process | es_ES |

| dc.type | Capítulo de libro | es_ES |

| dc.type | Comunicación en congreso | es_ES |

| dc.identifier.doi | 10.4995/AMPERE2019.2019.9870 | |

| dc.rights.accessRights | Abierto | es_ES |

| dc.description.bibliographicCitation | Deleu, W.; Goovaerts, V.; Groffils, C. (2019). Hybrid microwave with heat recovery for an efficient drying process. En AMPERE 2019. 17th International Conference on Microwave and High Frequency Heating. Editorial Universitat Politècnica de València. 159-165. https://doi.org/10.4995/AMPERE2019.2019.9870 | es_ES |

| dc.description.accrualMethod | OCS | es_ES |

| dc.relation.conferencename | Ampere 2019 | es_ES |

| dc.relation.conferencedate | Septiembre 09-12,2019 | es_ES |

| dc.relation.conferenceplace | Valencia, Spain | es_ES |

| dc.relation.publisherversion | http://ocs.editorial.upv.es/index.php/AMPERE2019/AMPERE2019/paper/view/9870 | es_ES |

| dc.description.upvformatpinicio | 159 | es_ES |

| dc.description.upvformatpfin | 165 | es_ES |

| dc.type.version | info:eu-repo/semantics/publishedVersion | es_ES |

| dc.relation.pasarela | OCS\9870 | es_ES |

Este ítem aparece en la(s) siguiente(s) colección(ones)

-

Ampere 2019 [66]