JavaScript is disabled for your browser. Some features of this site may not work without it.

Buscar en RiuNet

Listar

Mi cuenta

Estadísticas

Ayuda RiuNet

Admin. UPV

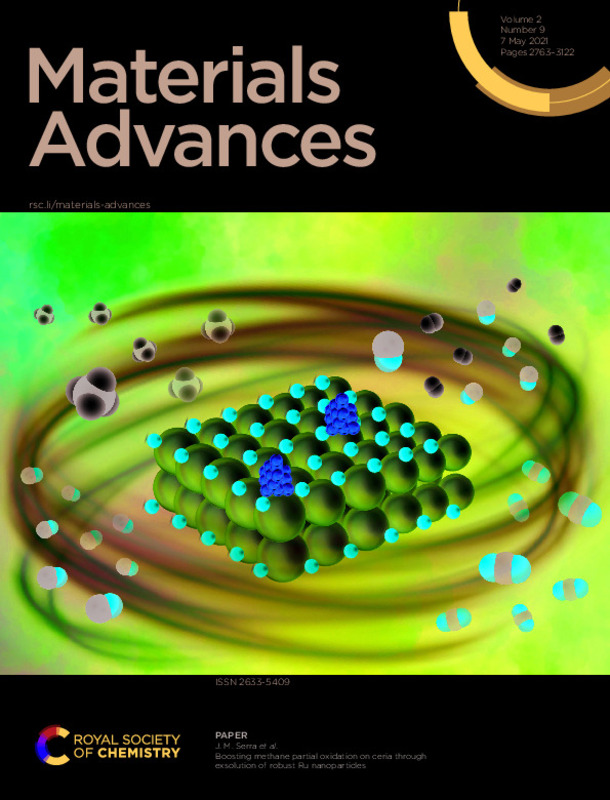

Boosting methane partial oxidation on ceria through exsolution of robust Ru nanoparticles

Mostrar el registro sencillo del ítem

Ficheros en el ítem

| dc.contributor.author | Carrillo-Del Teso, Alfonso Juan

|

es_ES |

| dc.contributor.author | Navarrete Algaba, Laura

|

es_ES |

| dc.contributor.author | Laqdiem-Marin, Marwan

|

es_ES |

| dc.contributor.author | Balaguer Ramirez, Maria

|

es_ES |

| dc.contributor.author | Serra Alfaro, José Manuel

|

es_ES |

| dc.date.accessioned | 2022-11-09T19:01:45Z | |

| dc.date.available | 2022-11-09T19:01:45Z | |

| dc.date.issued | 2021-05-07 | es_ES |

| dc.identifier.uri | http://hdl.handle.net/10251/189536 | |

| dc.description.abstract | [EN] Finding sustainable routes for the transformation of CO2 into fuels and added-value chemicals is key for mitigating greenhouse gas emission. In this respect, chemical-looping reforming coupled with CO2 splitting emerges as a promising technology to produce syngas, using waste or solar heat as an energy source. It relies on metal oxides that act as redox intermediates and, thus, the stability and catalytic activity of the oxides are crucial. For that purpose, ceria has been widely used due to its superior multicyclic stability and fast CO2 splitting kinetics. However, it also presents low capacity for oxygen exchange or supply compared with other oxides and slow methane partial oxidation kinetics, which is normally improved by cationic doping or catalytic surface activation via metal impregnation. The high temperatures (900 degrees C) required for these reactions lead to catalyst deactivation over time due to sintering of metallic clusters. In order to circumvent this issue, in this work we have utilized the exsolution method to create uniformly dispersed Ru nanoparticles (ca. 5 nm) that remain anchored to the cerium oxide backbone, guaranteeing its microstructural stability and catalytic activity over prolonged cycling. We provide evidence for metallic Ru exsolution and further demonstrate the outstanding benefits of exsolved nanoparticles in the partial oxidation of methane following a chemical-loop reforming scheme, especially in the temperature range in which industrial waste heat could be used as an energy source to drive the reaction. Remarkably, at 700 degrees C surface functionalization with exsolved Ru nanoparticles enables high CO selectivity (99% versus 62% for CeO2) and about 2 orders of magnitude faster H-2 production rates. The dispersion and size of the exsolved Ru nanoparticles were maintained after a durability test of 20 chemical loops at 900 degrees C, indicating their robustness. Overall, the results presented here point towards the unique characteristics of nanoparticle exsolution for preventing agglomeration, which could find application in other catalytic or electrochemical processes for target hydrocarbon production. | es_ES |

| dc.description.sponsorship | AJC and MB would like to acknowledge the support of Juan de la Cierva fellowships by the Spanish Ministry of Science (grant numbers FJCI-2017-33967 and IJCI-2017-34110). We acknowledge the support of the Electronic Microscopy Service of the Universitat Politecnica de Valencia. | es_ES |

| dc.language | Inglés | es_ES |

| dc.publisher | Royal Society of Chemistry | es_ES |

| dc.relation.ispartof | Materials Advances | es_ES |

| dc.rights | Reconocimiento - No comercial (by-nc) | es_ES |

| dc.title | Boosting methane partial oxidation on ceria through exsolution of robust Ru nanoparticles | es_ES |

| dc.type | Artículo | es_ES |

| dc.identifier.doi | 10.1039/d1ma00044f | es_ES |

| dc.relation.projectID | info:eu-repo/grantAgreement/MCIU//IJCI-2017-34110/ | es_ES |

| dc.relation.projectID | info:eu-repo/grantAgreement/MICINN//FJCI-2017-33967//Juan de la Cierva Formacion Program/ | es_ES |

| dc.rights.accessRights | Abierto | es_ES |

| dc.contributor.affiliation | Universitat Politècnica de València. Instituto Universitario Mixto de Tecnología Química - Institut Universitari Mixt de Tecnologia Química | es_ES |

| dc.description.bibliographicCitation | Carrillo-Del Teso, AJ.; Navarrete Algaba, L.; Laqdiem-Marin, M.; Balaguer Ramirez, M.; Serra Alfaro, JM. (2021). Boosting methane partial oxidation on ceria through exsolution of robust Ru nanoparticles. Materials Advances. 2(9):2924-2934. https://doi.org/10.1039/d1ma00044f | es_ES |

| dc.description.accrualMethod | S | es_ES |

| dc.relation.publisherversion | https://doi.org/10.1039/d1ma00044f | es_ES |

| dc.description.upvformatpinicio | 2924 | es_ES |

| dc.description.upvformatpfin | 2934 | es_ES |

| dc.type.version | info:eu-repo/semantics/publishedVersion | es_ES |

| dc.description.volume | 2 | es_ES |

| dc.description.issue | 9 | es_ES |

| dc.identifier.eissn | 2633-5409 | es_ES |

| dc.relation.pasarela | S\452700 | es_ES |

| dc.contributor.funder | Ministerio de Ciencia e Innovación | es_ES |

| dc.contributor.funder | Universitat Politècnica de València | es_ES |

| dc.contributor.funder | Ministerio de Ciencia, Innovación y Universidades | es_ES |