JavaScript is disabled for your browser. Some features of this site may not work without it.

Buscar en RiuNet

Listar

Mi cuenta

Estadísticas

Ayuda RiuNet

Admin. UPV

A performance comparison of single product kanban control systems

Mostrar el registro sencillo del ítem

Ficheros en el ítem

| dc.contributor.author | Ang, Alvin

|

es_ES |

| dc.date.accessioned | 2015-05-18T09:47:52Z | |

| dc.date.available | 2015-05-18T09:47:52Z | |

| dc.date.issued | 2015-01-30 | |

| dc.identifier.issn | 2340-5317 | |

| dc.identifier.uri | http://hdl.handle.net/10251/50377 | |

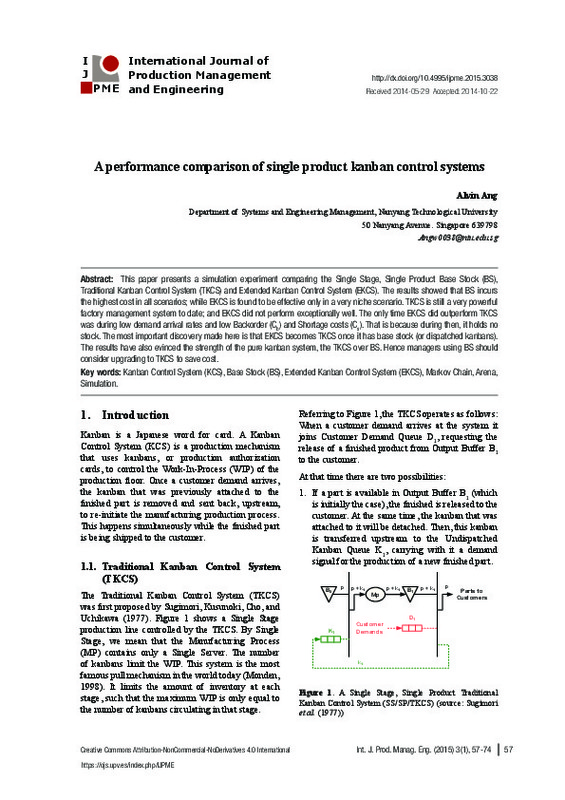

| dc.description.abstract | [EN] This paper presents a simulation experiment comparing the Single Stage, Single Product Base Stock (BS), Traditional Kanban Control System (TKCS) and Extended Kanban Control System (EKCS). The results showed that BS incurs the highest cost in all scenarios; while EKCS is found to be effective only in a very niche scenario. TKCS is still a very powerful factory management system to date; and EKCS did not perform exceptionally well. The only time EKCS did outperform TKCS was during low demand arrival rates and low Backorder (Cb) and Shortage costs (Cs). That is because during then, it holds no stock. The most important discovery made here is that EKCS becomes TKCS once it has base stock (or dispatched kanbans). The results have also evinced the strength of the pure kanban system, the TKCS over BS. Hence managers using BS should consider upgrading to TKCS to save cost. | es_ES |

| dc.language | Inglés | es_ES |

| dc.publisher | Editorial Universitat Politècnica de València | |

| dc.relation.ispartof | International Journal of Production Management and Engineering | |

| dc.rights | Reconocimiento - No comercial - Sin obra derivada (by-nc-nd) | es_ES |

| dc.subject | Kanban Control System (KCS) | es_ES |

| dc.subject | Base Stock (BS) | es_ES |

| dc.subject | Extended Kanban Control System (EKCS) | es_ES |

| dc.subject | Markov Chain | es_ES |

| dc.subject | Arena | es_ES |

| dc.subject | Simulation | es_ES |

| dc.title | A performance comparison of single product kanban control systems | es_ES |

| dc.type | Artículo | es_ES |

| dc.date.updated | 2015-05-18T07:32:43Z | |

| dc.identifier.doi | 10.4995/ijpme.2015.3038 | |

| dc.rights.accessRights | Abierto | es_ES |

| dc.description.bibliographicCitation | Ang, A. (2015). A performance comparison of single product kanban control systems. International Journal of Production Management and Engineering. 3(1):57-74. https://doi.org/10.4995/ijpme.2015.3038 | es_ES |

| dc.description.accrualMethod | SWORD | es_ES |

| dc.relation.publisherversion | https://doi.org/10.4995/ijpme.2015.3038 | es_ES |

| dc.description.upvformatpinicio | 57 | es_ES |

| dc.description.upvformatpfin | 74 | es_ES |

| dc.type.version | info:eu-repo/semantics/publishedVersion | es_ES |

| dc.description.volume | 3 | |

| dc.description.issue | 1 | |

| dc.identifier.eissn | 2340-4876 | |

| dc.description.references | Aghajani, M., Keramati, A., & Javadi, B. (2012). Determination of number of kanban in a cellular manufacturing system with considering rework process. The International Journal of Advanced Manufacturing Technology, 63(9-12), 1177-1189. doi:10.1007/s00170-012-3973-y | es_ES |

| dc.description.references | Al-Hawari, T., Aqlan, F. (2012). A software application for E-Kanban-based WIP control in the aluminium industry. International Journal of Modelling in Operations Management, 2(2): 119-137. | es_ES |

| dc.description.references | Ang, A., Piplani, R. (2010). A Model for Determining the Optimal Number of Base Stock and Kanbans in a Single Stage Extended Kanban Control System (EKCS). Paper presented at the Proceedings of the 5th AOTULE International Postgraduate Students Conference on Engineering. | es_ES |

| dc.description.references | Boonlertvanich, K. (2005). Extended-CONWIP-Kanban System: Control and Performance Analysis. (Ph.D.), Georgia Tech, USA. | es_ES |

| dc.description.references | Hopp, W. J., Spearman, M. L. (2008). Factory physics (3rd ed.). New York, NY: McGraw-Hill/Irwin/Irwin. | es_ES |

| dc.description.references | Monden, Y. (1983). Toyota production system: practical approach to production management. Norcross, GA: Industrial Engineering and Management Press, Institute of Industrial Engineers. | es_ES |

| dc.description.references | Monden, Y. (1998). Toyota production system : an integrated approach to just-in-time (3rd ed.). Norcross, Georgia: Engineering & Management Press. | es_ES |

| dc.description.references | Zipkin, P. H. (2000). Foundations of inventory management. Boston: McGraw-Hill | es_ES |