JavaScript is disabled for your browser. Some features of this site may not work without it.

Buscar en RiuNet

Listar

Mi cuenta

Estadísticas

Ayuda RiuNet

Admin. UPV

3D printed concrete blocks made with sustainable recycled material

Mostrar el registro sencillo del ítem

Ficheros en el ítem

| dc.contributor.author | Volpe, Stelladriana

|

es_ES |

| dc.contributor.author | Sangiorgio, Valentino

|

es_ES |

| dc.contributor.author | Petrella, Andrea

|

es_ES |

| dc.contributor.author | Notarnicola, Michele

|

es_ES |

| dc.contributor.author | Varum, Humberto

|

es_ES |

| dc.contributor.author | Fiorito, Francesco

|

es_ES |

| dc.date.accessioned | 2023-04-26T06:46:44Z | |

| dc.date.available | 2023-04-26T06:46:44Z | |

| dc.date.issued | 2023-04-04 | |

| dc.identifier.uri | http://hdl.handle.net/10251/192959 | |

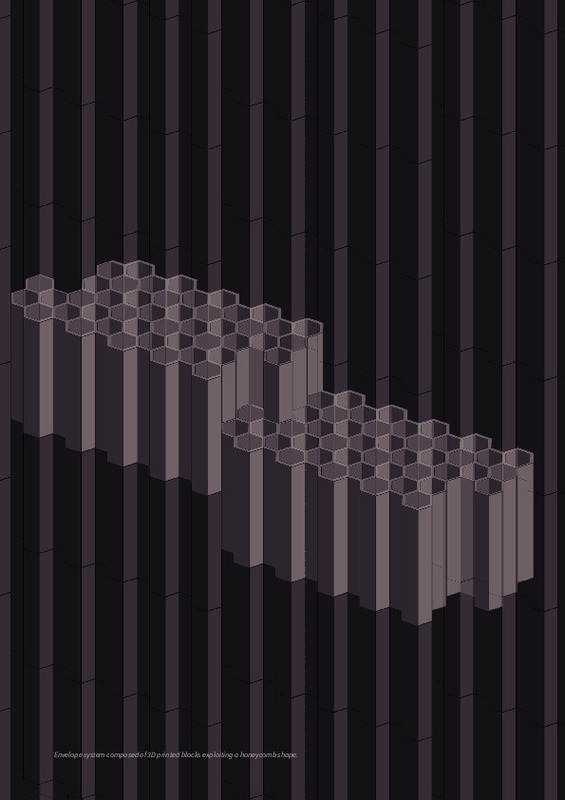

| dc.description.abstract | [EN] The use of recovered materials in building construction is one of the most effective strategies for reducing the environmental impacts of the construction sector. Innovative technologies such as 3D construction printing can be applied in combination with recycling strategies in order to optimise their performances also from an environmental point of view. In fact, several studies have proposed the processing of waste material into printable material. At the same time, performance studies must be conducted on the building components produced by these methods. This study proposes a methodological approach to design a 3D printable building component made with recycled materials considering the improvement of thermal performances. In particular, the approach is based on three steps: reuse strategy conception; target performance definition, modelling and iterative simulation; 3D printing setting. The methodological approach has been applied to a 3D printable block using as printable material a cement-based mortar with recycled aggregates and recycled insulating material. As a result, the component s shape (interlocking and inspired by honeycombs) can be customised to achieve the required thermal performance by using recycled materials in the printing process. | es_ES |

| dc.description.sponsorship | This research was funded by the European Union – European Social Fund – PON Research and Innovation 20214- 2020. | es_ES |

| dc.language | Inglés | es_ES |

| dc.publisher | Universitat Politècnica de València | es_ES |

| dc.relation.ispartof | VITRUVIO - International Journal of Architectural Technology and Sustainability | es_ES |

| dc.rights | Reconocimiento - No comercial (by-nc) | es_ES |

| dc.subject | 3D Construction Printing | es_ES |

| dc.subject | Recycled Material | es_ES |

| dc.subject | Thermal Performances | es_ES |

| dc.subject | Building envelope | es_ES |

| dc.subject | Thechnical architecture | es_ES |

| dc.subject | Building innovation and digitization | es_ES |

| dc.title | 3D printed concrete blocks made with sustainable recycled material | es_ES |

| dc.type | Artículo | es_ES |

| dc.identifier.doi | 10.4995/vitruvio-ijats.2023.18832 | |

| dc.rights.accessRights | Abierto | es_ES |

| dc.description.bibliographicCitation | Volpe, S.; Sangiorgio, V.; Petrella, A.; Notarnicola, M.; Varum, H.; Fiorito, F. (2023). 3D printed concrete blocks made with sustainable recycled material. VITRUVIO - International Journal of Architectural Technology and Sustainability. 8:70-83. https://doi.org/10.4995/vitruvio-ijats.2023.18832 | es_ES |

| dc.description.accrualMethod | OJS | es_ES |

| dc.relation.publisherversion | https://doi.org/10.4995/vitruvio-ijats.2023.18832 | es_ES |

| dc.description.upvformatpinicio | 70 | es_ES |

| dc.description.upvformatpfin | 83 | es_ES |

| dc.type.version | info:eu-repo/semantics/publishedVersion | es_ES |

| dc.description.volume | 8 | es_ES |

| dc.identifier.eissn | 2444-9091 | |

| dc.relation.pasarela | OJS\18832 | es_ES |

| dc.contributor.funder | European Social Fund | es_ES |

| dc.description.references | Adhikari, B., De, D., Maiti, S., (2000). Reclamation and recycling of waste rubber. Prog Polym Sci 25, 909–948. https://doi.org/10.1016/S0079-6700(00)00020-4 | es_ES |

| dc.description.references | Adhikary, S.K., Ashish, D.K., Rudžionis, Ž., (2021). Expanded glass as light-weight aggregate in concrete – A review. J Clean Prod 313, 127848. https://doi.org/10.1016/J.JCLEPRO.2021.127848 | es_ES |

| dc.description.references | Ahmad, M.R., Chen, B., (2018). Effect of silica fume and basalt fiber on the mechanical properties and microstructure of magnesium phosphate cement (MPC) mortar. Constr Build Mater 190, 466–478. https://doi.org/10.1016/J.CONBUILDMAT.2018.09.143 | es_ES |

| dc.description.references | Christen, H., van Zijl, G., de Villiers, W., (2022). The incorporation of recycled brick aggregate in 3D printed concrete. Cleaner Materials 4, 100090. https://doi.org/10.1016/J.CLEMA.2022.100090 | es_ES |

| dc.description.references | Colglazier, W., (2015). Sustainable development agenda: 2030. Science (1979) 349, 1048–1050. https://doi.org/10.1126/science. aad2333 | es_ES |

| dc.description.references | De Andrade Salgado, F., de Andrade Silva, F., (2022). Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. Journal of Building Engineering 52, 104452. https://doi.org/10.1016/J.JOBE.2022.104452 | es_ES |

| dc.description.references | Del Coz Díaz, J.J., García Nieto, P.J., Rodríguez, A.M., Martínez-Luengas, A.L., Biempica, C.B., (2006). Non-linear thermal analysis of light concrete hollow brick walls by the finite element method and experimental validation. Appl Therm Eng 26, 777–786. https://doi.org/10.1016/J.APPLTHERMALENG.2005.10.012 | es_ES |

| dc.description.references | Ding, T., Xiao, J., Zou, S., Wang, Y., (2020). Hardened properties of layered 3D printed concrete with recycled sand. Cem Concr Compos 113, 103724. https://doi.org/10.1016/j.cemconcomp.2020.103724 | es_ES |

| dc.description.references | Freitas, J. de S., Cronemberger, J., Soares, R.M., Amorim, C.N.D., (2020). Modeling and assessing BIPV envelopes using parametric Rhinoceros plugins Grasshopper and Ladybug. Renew Energy 160, 1468–1479. https://doi.org/10.1016/j.renene.2020.05.137 | es_ES |

| dc.description.references | Goode, A.H., Tyrrell, M.E., Feld, I.L., (1972). Glass wool from waste glass. US Department of Interior, Bureau of Mines. | es_ES |

| dc.description.references | Gustafsson, S.E., (1991). Transient plane source techniques for thermal conductivity and thermal diffusivity measurements of solid materials. Review of Scientific Instruments 62, 797–804. https://doi.org/10.1063/1.1142087 | es_ES |

| dc.description.references | Han, Y., Yang, Z., Ding, T., Xiao, J., (2021). Environmental and economic assessment on 3D printed buildings with recycled concrete. J Clean Prod 278, 123884. https://doi.org/10.1016/J.JCLEPRO.2020.123884 | es_ES |

| dc.description.references | Jeffrey, C., (2011). Construction and demolition waste recycling: A literature review. Dalhousie University’s Office of Sustainability 35. | es_ES |

| dc.description.references | Jianming, Y., Luming, W., Cheng, J., Dong, S., (2020). Effect of fly ash on the corrosion resistance of magnesium potassium phosphate cement paste in sulfate solution. Constr Build Mater 237, 117639. https://doi.org/10.1016/j.conbuildmat.2019.117639 | es_ES |

| dc.description.references | Le Duigou, A., Correa, D., Ueda, M., Matsuzaki, R., Castro, M., (2020). A review of 3D and 4D printing of natural fibre biocomposites. Mater Des 194, 108911. https://doi.org/10.1016/J.MATDES.2020.108911 | es_ES |

| dc.description.references | Liu, H., Liu, C., Wu, Y., Bai, G., He, C., Zhang, R., Wang, Y., (2022). Hardened properties of 3D printed concrete with recycled coarse aggregate. Cem Concr Res 159, 106868. https://doi.org/10.1016/J.CEMCONRES.2022.106868 | es_ES |

| dc.description.references | Liu, Z., Li, M., Weng, Y., Wong, T.N., Tan, M.J., (2019). Mixture Design Approach to optimize the rheological properties of the material used in 3D cementitious material printing. Constr Build Mater 198, 245–255. https://doi.org/10.1016/J.CONBUILDMAT.2018.11.252 | es_ES |

| dc.description.references | Lopez Hurtado, P., Rouilly, A., Vandenbossche, V., Raynaud, C., (2016). A review on the properties of cellulose fibre insulation. Build Environ 96, 170–177. https://doi.org/10.1016/j.buildenv.2015.09.031 | es_ES |

| dc.description.references | Majumder, A., Canale, L., Mastino, C.C., Pacitto, A., Frattolillo, A., Dell’Isola, M., (2021). Thermal Characterization of Recycled Materials for Building Insulation. Energies (Basel) 14. https://doi.org/10.3390/en14123564 | es_ES |

| dc.description.references | Medina, N.F., Medina, D.F., Hernández-Olivares, F., Navacerrada, M.A., (2017). Mechanical and thermal properties of concrete incorporating rubber and fibres from tyre recycling. Constr Build Mater 144, 563–573. https://doi.org/10.1016/J.CONBUILDMAT.2017.03.196 | es_ES |

| dc.description.references | Ministero dello Sviluppo Economico: Roma, (2015). Decreto Ministeriale 26 Giugno 2015. Applicazione Delle Metodologie di Calcolo Delle Prestazioni Energetiche e Definizione Delle Prescrizioni e dei Requisiti Minimi Degli Edifici, Governo Italiano. Italy. | es_ES |

| dc.description.references | Muthukrishnan, S., Kua, H.W., Yu, L.N., Chung, J.K.H., (2020). Fresh Properties of Cementitious Materials Containing Rice Husk Ash for Construction 3D Printing. Journal of Materials in Civil Engineering 32. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003230 | es_ES |

| dc.description.references | Panda, B., Lim, J.H., Tan, M.J., (2019). Mechanical properties and deformation behaviour of early age concrete in the context of digital construction. Compos B Eng 165, 563–571. https://doi.org/10.1016/J.COMPOSITESB.2019.02.040 | es_ES |

| dc.description.references | Qian, H., Hua, S., Yue, H., Feng, G., Qian, L., Jiang, W., Zhang, L., (2022). Optimizing the Application of Recycled Dust Powder in 3d Concrete Printing Materials Through Particle Densely Packing Theory. SSRN Electronic Journal. https://doi.org/10.2139/ssrn.4079313 | es_ES |

| dc.description.references | Ricciardi, P., Belloni, E., Cotana, F., (2014). Innovative panels with recycled materials: Thermal and acoustic performance and Life Cycle Assessment. Appl Energy 134, 150–162. https://doi.org/10.1016/J.APENERGY.2014.07.112 | es_ES |

| dc.description.references | Roussel, N., (2018). Rheological requirements for printable concretes. Cem Concr Res 112, 76–85. https://doi.org/10.1016/J.CEMCONRES.2018.04.005 | es_ES |

| dc.description.references | Sangiorgio, V., Parisi, F., Fieni, F., Parisi, N., (2022). The New Boundaries of 3D-Printed Clay Bricks Design: Printability of Complex Internal Geometries. Sustainability 14, 598. https://doi.org/10.3390/su14020598 | es_ES |

| dc.description.references | Streimikiene, D., Skulskis, V., Balezentis, T., Agnusdei, G.P., (2020). Uncertain multi-criteria sustainability assessment of green building insulation materials. Energy Build 219, 110021. https://doi.org/10.1016/J.ENBUILD.2020.110021 | es_ES |

| dc.description.references | Sun, S., Liu, R., Zhao, X., Zhang, Y., Yang, Y., (2019). Investigation on the water resistance of the fly-ash modified magnesium phosphate cement. IOP Conf Ser Mater Sci Eng 587, 12007. https://doi.org/10.1088/1757-899X/587/1/012007 | es_ES |

| dc.description.references | Ting, G.H.A., Tay, Y.W.D., Tan, M.J., (2021). Experimental measurement on the effects of recycled glass cullets as aggregates for construction 3D printing. J Clean Prod 300, 126919. https://doi.org/10.1016/J.JCLEPRO.2021.126919 | es_ES |

| dc.description.references | Tinoco, M.P., de Mendonça, É.M., Fernandez, L.I.C., Caldas, L.R., Reales, O.A.M., Toledo Filho, R.D., (2022). Life cycle assessment (LCA) and environmental sustainability of cementitious materials for 3D concrete printing: A systematic literature review. Journal of Building Engineering 52, 104456. https://doi.org/10.1016/J.JOBE.2022.104456 | es_ES |

| dc.description.references | Volpe, S., Petrella, A., Sangiorgio, V., Notarnicola, M., Fiorito, F., (2021a). Preparation and characterization of novel environmentally sustainable mortars based on magnesium potassium phosphate cement for additive manufacturing. AIMS Mater Sci 8, 640–658. https://doi.org/10.3934/matersci.2021039 | es_ES |

| dc.description.references | Volpe, S., Sangiorgio, V., Fiorito, F., n.d. (2022). Design of an efficient 3D printed envelope supported by parametric modelling, in: Colloqui.AT.e .Memoria e Innovazione. | es_ES |

| dc.description.references | Volpe, S., Sangiorgio, V., Petrella, A., Coppola, A., Notarnicola, M., Fiorito, F., (2021b). Building Envelope Prefabricated with 3D Printing Technology. Sustainability 13. https://doi.org/10.3390/su13168923 | es_ES |

| dc.description.references | Xu, X., Lin, X., Pan, X., Ji, T., Liang, Y., Zhang, H., (2020). Influence of silica fume on the setting time and mechanical properties of a new magnesium phosphate cement. Constr Build Mater 235, 117544. https://doi.org/10.1016/j.conbuildmat.2019.117544 | es_ES |

| dc.description.references | Zhang, H., Xiao, J., (2021). Plastic shrinkage and cracking of 3D printed mortar with recycled sand. Constr Build Mater 302, 124405. https://doi.org/10.1016/J.CONBUILDMAT.2021.124405 | es_ES |