Adhikari, B., De, D., Maiti, S., (2000). Reclamation and recycling of waste rubber. Prog Polym Sci 25, 909–948. https://doi.org/10.1016/S0079-6700(00)00020-4

Adhikary, S.K., Ashish, D.K., Rudžionis, Ž., (2021). Expanded glass as light-weight aggregate in concrete – A review. J Clean Prod 313, 127848. https://doi.org/10.1016/J.JCLEPRO.2021.127848

Ahmad, M.R., Chen, B., (2018). Effect of silica fume and basalt fiber on the mechanical properties and microstructure of magnesium phosphate cement (MPC) mortar. Constr Build Mater 190, 466–478. https://doi.org/10.1016/J.CONBUILDMAT.2018.09.143

[+]

Adhikari, B., De, D., Maiti, S., (2000). Reclamation and recycling of waste rubber. Prog Polym Sci 25, 909–948. https://doi.org/10.1016/S0079-6700(00)00020-4

Adhikary, S.K., Ashish, D.K., Rudžionis, Ž., (2021). Expanded glass as light-weight aggregate in concrete – A review. J Clean Prod 313, 127848. https://doi.org/10.1016/J.JCLEPRO.2021.127848

Ahmad, M.R., Chen, B., (2018). Effect of silica fume and basalt fiber on the mechanical properties and microstructure of magnesium phosphate cement (MPC) mortar. Constr Build Mater 190, 466–478. https://doi.org/10.1016/J.CONBUILDMAT.2018.09.143

Christen, H., van Zijl, G., de Villiers, W., (2022). The incorporation of recycled brick aggregate in 3D printed concrete. Cleaner Materials 4, 100090. https://doi.org/10.1016/J.CLEMA.2022.100090

Colglazier, W., (2015). Sustainable development agenda: 2030. Science (1979) 349, 1048–1050. https://doi.org/10.1126/science. aad2333

De Andrade Salgado, F., de Andrade Silva, F., (2022). Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. Journal of Building Engineering 52, 104452. https://doi.org/10.1016/J.JOBE.2022.104452

Del Coz Díaz, J.J., García Nieto, P.J., Rodríguez, A.M., Martínez-Luengas, A.L., Biempica, C.B., (2006). Non-linear thermal analysis of light concrete hollow brick walls by the finite element method and experimental validation. Appl Therm Eng 26, 777–786. https://doi.org/10.1016/J.APPLTHERMALENG.2005.10.012

Ding, T., Xiao, J., Zou, S., Wang, Y., (2020). Hardened properties of layered 3D printed concrete with recycled sand. Cem Concr Compos 113, 103724. https://doi.org/10.1016/j.cemconcomp.2020.103724

Freitas, J. de S., Cronemberger, J., Soares, R.M., Amorim, C.N.D., (2020). Modeling and assessing BIPV envelopes using parametric Rhinoceros plugins Grasshopper and Ladybug. Renew Energy 160, 1468–1479. https://doi.org/10.1016/j.renene.2020.05.137

Goode, A.H., Tyrrell, M.E., Feld, I.L., (1972). Glass wool from waste glass. US Department of Interior, Bureau of Mines.

Gustafsson, S.E., (1991). Transient plane source techniques for thermal conductivity and thermal diffusivity measurements of solid materials. Review of Scientific Instruments 62, 797–804. https://doi.org/10.1063/1.1142087

Han, Y., Yang, Z., Ding, T., Xiao, J., (2021). Environmental and economic assessment on 3D printed buildings with recycled concrete. J Clean Prod 278, 123884. https://doi.org/10.1016/J.JCLEPRO.2020.123884

Jeffrey, C., (2011). Construction and demolition waste recycling: A literature review. Dalhousie University’s Office of Sustainability 35.

Jianming, Y., Luming, W., Cheng, J., Dong, S., (2020). Effect of fly ash on the corrosion resistance of magnesium potassium phosphate cement paste in sulfate solution. Constr Build Mater 237, 117639. https://doi.org/10.1016/j.conbuildmat.2019.117639

Le Duigou, A., Correa, D., Ueda, M., Matsuzaki, R., Castro, M., (2020). A review of 3D and 4D printing of natural fibre biocomposites. Mater Des 194, 108911. https://doi.org/10.1016/J.MATDES.2020.108911

Liu, H., Liu, C., Wu, Y., Bai, G., He, C., Zhang, R., Wang, Y., (2022). Hardened properties of 3D printed concrete with recycled coarse aggregate. Cem Concr Res 159, 106868. https://doi.org/10.1016/J.CEMCONRES.2022.106868

Liu, Z., Li, M., Weng, Y., Wong, T.N., Tan, M.J., (2019). Mixture Design Approach to optimize the rheological properties of the material used in 3D cementitious material printing. Constr Build Mater 198, 245–255. https://doi.org/10.1016/J.CONBUILDMAT.2018.11.252

Lopez Hurtado, P., Rouilly, A., Vandenbossche, V., Raynaud, C., (2016). A review on the properties of cellulose fibre insulation. Build Environ 96, 170–177. https://doi.org/10.1016/j.buildenv.2015.09.031

Majumder, A., Canale, L., Mastino, C.C., Pacitto, A., Frattolillo, A., Dell’Isola, M., (2021). Thermal Characterization of Recycled Materials for Building Insulation. Energies (Basel) 14. https://doi.org/10.3390/en14123564

Medina, N.F., Medina, D.F., Hernández-Olivares, F., Navacerrada, M.A., (2017). Mechanical and thermal properties of concrete incorporating rubber and fibres from tyre recycling. Constr Build Mater 144, 563–573. https://doi.org/10.1016/J.CONBUILDMAT.2017.03.196

Ministero dello Sviluppo Economico: Roma, (2015). Decreto Ministeriale 26 Giugno 2015. Applicazione Delle Metodologie di Calcolo Delle Prestazioni Energetiche e Definizione Delle Prescrizioni e dei Requisiti Minimi Degli Edifici, Governo Italiano. Italy.

Muthukrishnan, S., Kua, H.W., Yu, L.N., Chung, J.K.H., (2020). Fresh Properties of Cementitious Materials Containing Rice Husk Ash for Construction 3D Printing. Journal of Materials in Civil Engineering 32. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003230

Panda, B., Lim, J.H., Tan, M.J., (2019). Mechanical properties and deformation behaviour of early age concrete in the context of digital construction. Compos B Eng 165, 563–571. https://doi.org/10.1016/J.COMPOSITESB.2019.02.040

Qian, H., Hua, S., Yue, H., Feng, G., Qian, L., Jiang, W., Zhang, L., (2022). Optimizing the Application of Recycled Dust Powder in 3d Concrete Printing Materials Through Particle Densely Packing Theory. SSRN Electronic Journal. https://doi.org/10.2139/ssrn.4079313

Ricciardi, P., Belloni, E., Cotana, F., (2014). Innovative panels with recycled materials: Thermal and acoustic performance and Life Cycle Assessment. Appl Energy 134, 150–162. https://doi.org/10.1016/J.APENERGY.2014.07.112

Roussel, N., (2018). Rheological requirements for printable concretes. Cem Concr Res 112, 76–85. https://doi.org/10.1016/J.CEMCONRES.2018.04.005

Sangiorgio, V., Parisi, F., Fieni, F., Parisi, N., (2022). The New Boundaries of 3D-Printed Clay Bricks Design: Printability of Complex Internal Geometries. Sustainability 14, 598. https://doi.org/10.3390/su14020598

Streimikiene, D., Skulskis, V., Balezentis, T., Agnusdei, G.P., (2020). Uncertain multi-criteria sustainability assessment of green building insulation materials. Energy Build 219, 110021. https://doi.org/10.1016/J.ENBUILD.2020.110021

Sun, S., Liu, R., Zhao, X., Zhang, Y., Yang, Y., (2019). Investigation on the water resistance of the fly-ash modified magnesium phosphate cement. IOP Conf Ser Mater Sci Eng 587, 12007. https://doi.org/10.1088/1757-899X/587/1/012007

Ting, G.H.A., Tay, Y.W.D., Tan, M.J., (2021). Experimental measurement on the effects of recycled glass cullets as aggregates for construction 3D printing. J Clean Prod 300, 126919. https://doi.org/10.1016/J.JCLEPRO.2021.126919

Tinoco, M.P., de Mendonça, É.M., Fernandez, L.I.C., Caldas, L.R., Reales, O.A.M., Toledo Filho, R.D., (2022). Life cycle assessment (LCA) and environmental sustainability of cementitious materials for 3D concrete printing: A systematic literature review. Journal of Building Engineering 52, 104456. https://doi.org/10.1016/J.JOBE.2022.104456

Volpe, S., Petrella, A., Sangiorgio, V., Notarnicola, M., Fiorito, F., (2021a). Preparation and characterization of novel environmentally sustainable mortars based on magnesium potassium phosphate cement for additive manufacturing. AIMS Mater Sci 8, 640–658. https://doi.org/10.3934/matersci.2021039

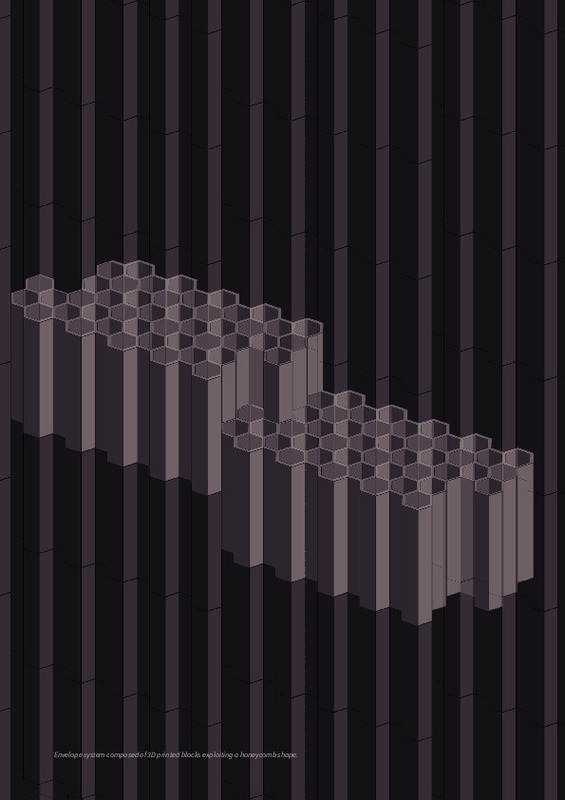

Volpe, S., Sangiorgio, V., Fiorito, F., n.d. (2022). Design of an efficient 3D printed envelope supported by parametric modelling, in: Colloqui.AT.e .Memoria e Innovazione.

Volpe, S., Sangiorgio, V., Petrella, A., Coppola, A., Notarnicola, M., Fiorito, F., (2021b). Building Envelope Prefabricated with 3D Printing Technology. Sustainability 13. https://doi.org/10.3390/su13168923

Xu, X., Lin, X., Pan, X., Ji, T., Liang, Y., Zhang, H., (2020). Influence of silica fume on the setting time and mechanical properties of a new magnesium phosphate cement. Constr Build Mater 235, 117544. https://doi.org/10.1016/j.conbuildmat.2019.117544

Zhang, H., Xiao, J., (2021). Plastic shrinkage and cracking of 3D printed mortar with recycled sand. Constr Build Mater 302, 124405. https://doi.org/10.1016/J.CONBUILDMAT.2021.124405

[-]